University of California, Irvine

Instructor: Dr. Barbara J. Becker

|

Lecture 11. Extending Material Capabilities

|

For centuries humans relied on muscle power to drive their machines and transport heavy loads. Living sentient beings can be trained to operate devices and retrained when conditions warrant a change, but they must be fed, sheltered and given adequate time to rest in order to work at optimum capacity. Water and wind can move machines, too. They require no food, shelter or rest, so can be used perpetually at no cost. But they vary, often unpredictably, in their availability, strength and direction of flow. Machines that rely on them for power are subject to the whims of Nature. A new relationship between man and machine emerged with the development of innovative methods for harnessing water and wind to derive the greatest benefit from their natural strength and direction. Man-made reservoirs and systems of artificial channels kept waterwheels supplied with an adequate and steady flow of water. The lateen sail and the technique of "tacking" converted sailboats from passive responders to wind action into flexible masters of the wind. Windmills capable of rotating so their sails were always turned into the wind provided a more reliable source of power for these machines. Seventeenth-century advocates of the New Philosophy helped push the technological envelope into uncharted territory. Coupling science and technology linked methodical study and testing with the craftsman's traditional cut and try approach to innovation. Achievements included mastery of the law of refraction which helped opticians shape lenses for magnifiers, telescopes and microscopes that changed how humans viewed their place in the world system. Mastery of the physical laws that govern the behavior of water and air made it possible to generate motive power when and where it is needed, even places that had no reliable source of wind or water. The development of efficient pumps driven by steam power was crucial in an age when miners operated pumps night and day with teams of strong horses used in shifts and still could not keep the mines properly drained. |

|

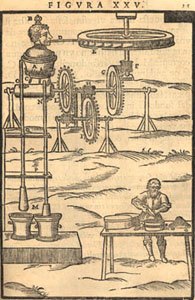

The first published illustration of a steam-operated turbine.

Le Machine (1629) by Giovanni Branca (1571-1640) |

| c. 1642

Gasparo Berti (c. 1600-1643) Filled vertical 36-ft long tube with water When valve was opened at the base of the tube, why didn't all the water run out? What was left in the empty space at the top of the tube? |

|

|

Evangelista Torricelli (1608-1647) developed Berti's experiments

further.

Torricelli concluded:

|

|

|

In 1654, Otto von Guericke (1602-1686) pumped most of the air out of the space enclosed by two brass hemispheres. While in that condition, the hemispheres could not be separated, even by two eight-horse teams pulling with all their strength. The pressure exerted on the hemispheres' outer surface by the atmosphere was crushingly powerful! As soon as air was allowed inside the two hemispheres again, they could be separated with ease. News of von Guericke's success inspired Robert Boyle (1627-1691) to conduct similar experiments with an air pump constructed by his assistant, Robert Hooke (1635-1703).

In 1673, Christiaan Huyghens (1629-1695) and Denis Papin (1647-c.1712) exploded a small amount of gunpowder in a vertical cylinder.

Papin's small steam-operated piston could lift as much as 60 pounds.

By heating and cooling the water-filled cylinder, the piston could be raised

and lowered over and over again.

|

|

|

| In 1698, Thomas Savery (1650-1715) obtained a patent for a steam-driven

engine to drain mines that operated at a rate of 5 cycles per minute.

In 1702 he published a small book describing his invention -- The

Miner's Friend.

In 1712, Thomas Newcomen (1663-1729) introduced his own steam-driven

pumping engine. During a trial of an early model of his engine, a

little cool water inadvertantly leaked into the cylinder causing the steam

in it to condense rapidly. Instead of lowering gradually, the piston

came crashing down with such a powerful force that it broke through the

bottom of the cylinder and broke the top of the boiler!! Newcomen

suddenly realized how much work (damage??) a steam engine could really

do! Now, if only he could replicate and then tame the conditions

that caused the accident....

|

|

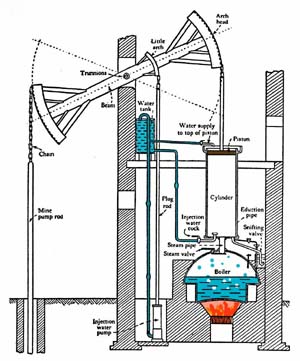

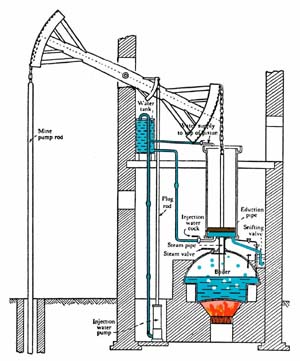

The Boiler continuously generates steam. The Piston is kept up at the top of the Cylinder--NOT by pressure from the steam, but by the fact that the Mine-Pump-Rod arm of the Beam (left) weighs more than the Piston arm (right). |

|

When the valve above the Boiler is opened, steam enters and

fills the Cylinder.

The Piston remains at the top of the Cylinder due to the unequal distribution of weight on the Beam. |

|

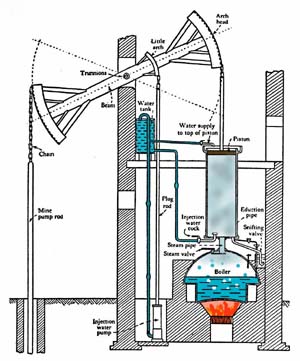

The Boiler valve is closed, trapping the steam in the Cylinder.

The accident that destroyed his early engine taught Newcomen a valuable lesson about steam. He changed his engine design in order to optimize the power that could be gained from the Piston's downstroke. Instead of cooling the Cylinder gradually by spraying its exterior as Papin and Savery had done, Newcomen inserted a pipe to spray cool water inside the Cylinder to condense the steam rapidly. |

|

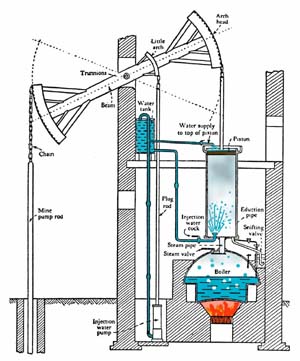

When the steam condenses, there is very little pressure left in the

Cylinder

to resist the force of the atmosphere above the Piston.

As the Piston is pushed downward by the atmosphere's pressure , it pulls the Piston arm of the Beam down with it. This action lifts the Mine-Pump-Rod arm of the Beam. The engine was able to operate at a rate of 15-16 cycles per minute. |

|

|

James Watt (1736-1819) After putting a broken Newcomen engine back in working order, James Watt concluded that the efficiency of the engine suffered from having the cylinder serve as both the container for the hot steam from the boiler and the place where that steam was cooled. He reasoned that each stroke would take up far less time and fuel if the cylinder were maintained at a high temperature thus avoiding having to reheat it during each cycle. He also recognized that the expansion of the steam could be harnessed as a motive force in the process.

Watt's Single Acting Steam Engine (1769) The Newcomen engine freed thousands of men and horses from the hard physical labor of keeping mines clear of water. These men were not released to hours of leisure, but rather from one dull job to another, or even no job at all. Although the Newcomen engine was very popular in its day, it had its limitations: a lot of heat was lost in its operation and it produced no rotary motion that could be applied to milling purposes. |

|