SPRING QUARTER, 2006

Department of History

University of California, Irvine

Instructor: Dr. Barbara J. Becker

|

Lecture 19. Spare Parts

|

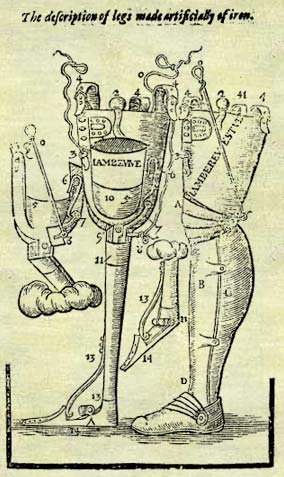

excerpts (with illustrations) from

An Explanation of the Fashion and Use of Book 23, Chapter 12. By what meanes armes, legs, and hands may be made by art, and placed instead of the naturall armes, legs, or hands that are cut off and lost.

|

|

|

150 Years of Artificial Limb Design |

_____________ March 26, 1855 Artificial Limbs. We all remember how the schoolboys looked up from their marbles and ceased from playing ball when the "man with the wooden leg" pegged by. It was a great wonder, that wooden leg -- so convenient in its insensibility, so curious in replacing, though imperfectly, a bona fide leg of flesh and bone. It was a very rude affair -- a cushioned butt and a tapering stick below, which, taken as a whole, very closely resembled a worn-down and curtailed broom-stick. It is not quite obsolete yet. We see it sometimes in our walks about the City; indeed, if we look out of our office window we see a couple of them, propping as well as they may, an old soldier, who peddles TIMES, Heralds, and Tribunes, as cheap as the cheapest, and without any Chatham-street importunity to customers. But these primitive wooden legs have not increased in a ratio proportionate to the increase of the people, to the number of capital operations that are performed, nor to the crowds of ambitious surgeons, who dream of their first amputation as the beginning of their career. The "peg legs" are "fading out;" but, meanwhile, it is marvellous how many people whose calves are not a bit attenuated, whose ankles are well-turned, and the motions of their knee-joints perfect, walk with a curious halt, as if, a long time ago, they had suffered rheumatism. A gentleman walked into our office, a few weeks ago, and candidly confessed, to our surprise, that he had an artificial leg on, and requested us to say which it was. After he had taken a few turns up and down the room, we guessed the left one; he quitely stripped up the pantaloon, and showed us that the right one was not made of flesh; but we confessed to a double surprise on discovering that, though he seemed like a well-formed man, the whole of the lower third of his body was a curious construction of wood and leather. One leg, to near the knee, and the other, to a point above it, were the work of art. We have met him since in Broadway, marching off so independently, without a crutch or substantial cane, that not one in a hundred would suspect that he had suffered anything worse in his locomotive organs than perhaps the presentiment of a coming East wind in rheumatic knee-joints. The best artificial limbs that we have seen -- and we may say so modestly, since at the London World's Fair they took the premium away from thirty eager competitors, and at our own Crystal Palace the highest award, since they have a string of premiums altogether too "numerous to mention," and the most unlimited praises of the first living surgeons -- are those of PALMER & Co's patent. Specimens of them are to be seen at No. 378 Broadway. They are constructed of willow, covered with parchment, painted a flesh color and beautifully enameled; are remarkably light and are not burdensome in their attachments. Perfect ventilation is secured to the stump. The knee joint, being a successful imitation of the ball and socket joint, avoids the deformity that the ordinary tenon and mortice joint exposes upon bending the limb. The ankle and toe joints are also imitated, and cords, operated by springs, cams and eccentrics, and the stump of the leg, enable the one who uses this contrivance to feel a degree of certainty in its movements that is very surprising.... |

_______________ February 26, 1859 Palmer's Artificial Limbs One of the great misfortunes of humanity is the loss of a limb; whether it be an arm or leg, the calamity is equally distressing, or we should say, was; for since B. Frank Palmer, of Philadelphia, has turned his attention to the subject, much of the distress is alleviated, and the personal appearance not at all injured....

The articulations of knee, ankle, and toes, consist of detached ball-and-socket joints, A B C. The knee and ankle are articulated by means of the steel bolts, E E, combining with plates of steel firmly riveted to the sides of the leg, D D. To these side plates are immoveably fastened the steel bolts, E E. The bolts take bearings in solid wood ... across the entire diameter of the knee and ankle, being much more reliable and durable than those of the usual construction. All the joints are so constructed that no two pieces of metal move against each other in the entire limb. The contact of all broad surfaces is avoided where motion is required, and thus friction is reduced to the lowest degree possible. These joints often perform many months without need of oil, or other attention -- a desideratum fully appreciated by the wearer. The Tendo Achilles, or heel tendon, F, perfectly imitates the natural one. It is attached to the bridge, G, in the thigh, and passing down on the back side of the knee bolt, E, is firmly fastened to the heel. It acts through the knee bolt on a center, when the weight is on the leg, imparting security and firmness to the knee and ankle joints, thus obviating all necessity for knee-catches. When the knee bends in taking a step, this tendon vibrates from the knee bolt to the back side of the thigh. It descends through the leg, so as to allow the foot to rise above all obstructions in flexion, and carries the foot down again, in extension of the leg for the next step, so as to take a firm support on the ball of the foot. Nature-like elasticity is thus attained, and all thumping sounds are avoided.... But the most ingenious piece of mechanism, and one that seems to us as likely to do greater service for humanity in relieving them from the deprivation of enjoyment and capability to work which generally follows an accident, is the arm and hand, of which we present full drawings.

The fingers are articulated on steel rods and pinions imitating the bones, as seen in the thumb and the first and third fingers. The exterior is brought to a perfect imitation of the natural arm (as shown in the outline, or in Fig. 5,) by a soft elastic substance, which rotates around the fore-arm, preserving anatomical symmetry in every position. It is covered with a delicate skin. Fig. 2 is the same arm extended, with the fingers semi-flexed. The belt, A, attaches the arm to the body. The small belt, C C2, is connected by a tendon to a clasp and pulley, D E. The great muscle, F, is the continuity of the flexor tendons, G H I J K. These tendons pass sinuously over pulleys or fixed sheaves, 1 2 3 4 5, through the hand, to the end of the fingers and thumb. The principles of the lever and pulley are thus combined, and the maximum power retained at all angles of flexion or extension. A slight motion of the shoulders, with extension of the fore-arm, produces an incredible grasp, as seen in Fig. 3. An object of any shape, such as a pen, a fork, or an apple, is held with facility. By a slight motion of the shoulders, the belt, A B, causes the great muscle, F, and its tendons, to contract powerfully, closing the hand. A movement easily and naturally made actuates the tendon, C C, and fastens the clasp, D, upon the muscle, so as to retain the grasp in any position or motion of the arm, when in use. This is regarded as invaluable for holding reins in driving, or carrying articles with safety. An easy counter motion unfastens the clasp, relaxing the flexor muscle and its tendons, and the extensors open the hand. This principle performs most perfectly in an arm applied below the elbow, as in Fig. 3. In this are seen the belt, A B C, the great muscle, F, and its tendons, the clasp and pulley, D E, as in Fig. 2. A fixed eyelet, F2, clasps the great muscle, F, and thus guides the flexor tendons of the fingers. The line, 1, shows the union of the natural with the artificial arm. Fig. 4 shows a hand holding a fork. The tendon, A A2, passes through the clasp, B, and around the pulley, C, to the side of the clasp, D, where it fastens or unfastens the clasp by movements before explained. The joints of the fingers and thumb are flexed upon the fork by powerful tension of the great muscle and its tendons.... |

_______________ September 22, 1861 Palmer's Artificial Limb. Mr. B. FRANK PALMER, the inventor and manufacturer of the artificial limb, which bears his name has recently tendered to the Government his services, with the free use of his time and abilities, for the assistance of the halt and mutilated of our armies. Congress, it will be remembered, passed an apporpriation of $15,000 for the purchase of artificial limbs for such; and Mr. PALMER, whose invention is recognized by the various scientific bodies of Europe and America as infinitely beyond that of any other, desirous that the soldiers should have none but the best, has generously offered to take the sum specified, and to apply it, without profit to himself, to the construction of as many of his artificial limbs as the amount will pay for.... |

______________ October 24, 1863 Improved Artificial Leg The inventor [Uriah Smith from Battle Creek, Michigan] of the artificial leg herewith illustrated, has worn a full length one for the past eighteen years; he has tried various kinds on other principles, and consequently claims to be pretty thorouughly acquainted with their deficiencies when brought into actual use. His object has been to imitate nature more closely than has yet been done, and produce a leg embracing all the advantages it is possible to embody in an artificial limb....

The advantages claimed for this leg are as follows: The knee joint will bend back to the full extent of the natural limb, as shown in Fig. 3, thus relieving the wearer from the cramped and uncomfortable positions which constantly occur with a leg that will bend only half way; and also that it enables the wearer to assume any position that he could with the natural limb. All who wear artificial legs will at once appreciate this. A solid and continuous support of wood is obtained from the body to the ground; dispensing with the use of bolts, and forming the most simple and sure bearings that can be obtained. All springs in the leg are dispensed with; thus avoiding the necessity of frequent repairs. A distinct spring in the ankle joint in other legs, keeps the toes elevated when the wearer is sitting, and the foot is relieved from pressure; which is an awkward position. With this leg, when the person is seated, the cord, L, is relaxed, allowing the toes to drop into their natural position. Legs which have a distinct spring attached to the knee joint, necessarily tax that spring to its utmost, when the leg is bent as in the sitting posture; which is unnatural and unphilosophical, and being in this position so great a portion of the time as it must necessarily be, the spring will eventually lose its elasticity, and become inoperative. With this leg, when a person is in the sitting posture, the cord, L, is relaxed, and the elastic, R, relieved from all tension whatever; no strain coming upon it except in the act of walking, which is the only time when the action of any spring is required. Being thus relieved except when walking, it is always ready to act at that time, and there can scarcely be any limit to its durablility. This elastic which operates both the knee and ankle joints, being inserted, not in but above the leg, its tension can be reegulated by the wearer with the utmost convenience, without even removing the limb. In addition to the foregoing specific points, this leg is claimed to be superior to all others, in lightness, simplicity of construction, ease of repair if damaged by accident, absence of friction, and consequent durability.... |

____________ April 15, 1865 Artificial Limbs. The engravings published herewith represent artificial limbs which have novel features not heretofore obtained in them. India-rubber is largely used in their construction, the feet and hands particularly being constructed of this substance.

No. 1 presents a full length leg standing erect, so to be applied in all cases where amputation occurs above the knee joint. No. 2 represents a leg to be applied where the leg has been amputated below the knee joint, and the stump is flexible enough, and sufficiently long, to enable the wearer to use it in walking. It also represents the leg with the heel compressed, and in its position after taking the step, and when firmly planted on the ground. No. 3 is termed a knee bearing leg; it is to be applied where amputation takes place below the knee, and where the stump is too short, or contracted at right angles, so the knee joint cannot be used in walking. This figure represents the leg slightly bent at the knee, and bearing well upon the toe, as in the act of lifting it to take the next advance step. No. 4 is a view of the India-rubber foot before being applied to the leg. This rubber foot constitutes the main feature in the legs shown in the figures. This foot is made mostly of [I]ndia-rubber of a very spongy, light and elastic character. A piece of willow wood, nearly filling the rubber heel at the top or surface, where the leg rests, runs down about one-fourth of the distance towards the lower part of the heel; also forward and downwards to the joint at the ball of the foot, as shown by the dotted line. This piece of wood is the base upon which the foot is built, and is also the medium whereby the foot is joined firmly to the leg. The leg itself is made of light, tough willow, in all cases except the thigh piece shown in figure 2, and the front part of the thigh piece in figure 3, which are both made of leather. The entire leg and foot in all cases is covered with fine buckskin, neatly coated with a life-like water-proof finish, making it both light and strong. It will be seen that there are no movable ankle joints in these limbs the necessity for which being entirely obviated by the elastic rubber foot, which gives all the motion required in walking, and also the ease, firmness, elasticity and reliance absolutely necessary in a perfect artificial leg. It would seem at first sight that no one could walk well on any artificial leg without the moving, flapping ankle joint, but practice proves this to be erroneous. The rubber foot, also, gives all the required lateral motion to the foot when stepping upon sidling or uneven ground. This leg dispenses with all machinery of whatever character, and has been in use for the last two years giving great saitsfaction.... Figure 6 shows a rubber hand, made same as the foot, of which there can not be as much said, as of the other inventions. It corresponds, however, with the others, in its characteristic features of simplicity and durability, and wholly dispenses with machinery, giving a softness to the feeling and an elasticity which is very desirable. It is as useful as any hand yet invented, which is not probably saying much in its favor, as no art yet shown, if it ever will, can compare with "nature's handiwork.".... |

________________ December 12, 1969 They're Not Robots, They're Cyborgs

Standing clumsily in a cluttered machineshop workroom at the General Electric Company plant in Schenectady, N.Y., is an 11-foot-tall, 3,000-pound monster of aluminum beams and hydraulic tubing which, at best, looks like some precocious child's attempt to build an elephant out of an overgrown Erector set. This mechanical elephant -- alternately called a "walking truck" or "quadruped" by Ralph S. Mosher, the engineer who designed it -- is the most striking member of a rapidly evolving family of new devices known as cyborgs. They are not artificially intelligent automatons, capable of performing on their own, with man playing the role only of a programer, but by combining man and machine in new working relationships, they show promise of fulfilling many of the hypothetical functions of Capek's robots. Human beings have been finding means of modifying or increasing their natural abilities since the first ape man picked up a bone or stick to extend the actions of his own arm.... Only within the past three decades has a growing body of scientists and technicians begun to study systematically the interaction between man and his tools, and to devise new technology for more efficient cooperation between them. The two basic principles are the design of the mechanical tools to follow or mimic a man's own natural movements like a slave obeying a master, and the provision of a two-way flow of commands and responses between the man and the mechanical slave.... [S]cientists and engineers working this field have yet to settle on a definitive term to mark their enterprises. "Robot" is not applicable because it does not acknowledge the key human element. In fact, most of the augmentation researchers shy away from the word "robot" because, like the monster of Mary Shelley's "Frankenstein," it has come to connote all that seems sinister or grotesque about man's attempts at creation in his own image (although the word "robot" came into the language from Capek's play, "R.U.R." -- "Rossum's Universal Robots," after their fictional inventor -- and is simply derived from "robota," the Czech word for "work). Casting about for a suitably descriptive word, human augmentation researchers have coined and discarded such catch-all terms as "telecheric" (a combination of Greek words to form "distant hand"), "telepuppet" and "telefactor." Engineers in the field most frequently use "master-slave," and "teleoperator," a rather loose word that blankets almost any sort of device that works at a distance from its human operator. In referring to the flow of information between man-operator and machine-slave, another term often used is "cybernetics," coined from the Greek "kybernetes," or "steersman," by Norbert Wiener, the late M.I.T. mathematician and a pioneer worrier about the complex new relations evolving between man and modern machines.... The most apt word has yet to find widespread use. It is a superhybrid: "cyborg" -- a combination of "cybernetic" and "organism," coined less than 10 years ago by Drs. Manfred Clynes and Nathan Kline, researchers at Rockland State Hospital in Orangeburg, N.Y., conducting studies into basic functions of human perception, emotion and reaction.... [T]he basic principles which are applicable to much of this work have been discovered almost accidentally only since the end of World War II. The pathfinding was done by a handful of engineers ... [who] wanted only to devise practical tools for scientists who needed to handle materials within the radioactive environment of atomic piles.... In 1947 [Raymond C. Goertz] devised the first crude grippers for handling nuclear materials. They were plierslike in that they fed no information back to the operator, but they were maneuverable and had what the engineers call "spatial correspondence" -- i.e., the gripper mimicked the movement of the operator in direct proportion to his movement.... In 1954, Mosher demonstrated the versatility that could be obtained ... when he constructed a pair of arms which could pick up more than 75 pounds or twirl a hula hoope -- the latter an exercise that, though it may be performed by a child, requires instantaneous interaction of senses and coordination in all six directions, using a total of 18 movements.... In 1958, a television camera was added to a manipulator system to add the sense of remote vision.... In the normal human hand, there are 22 possible individual movements.... The human leg, by comparison has eight basic motions in walking, augmented by three distinct pelvic motions and, according to Mosher, with "something like 13 axes in the ankle, you can identify between 10 and 20 additional motions of the foot." The degree to which future cyborg devices can be made to duplicate human action depends only upon how much time and money developers are willing to invest -- but, Mosher argues, it is putting icing on the cake. "Duplication of all 22 motions of the human hand is possible," he says. "The question is: 'Is it practical?' I find it pointless to build a sophisticated hand unless there is a use for it. I'm interested in building a mechanism that works with whatever compromises are necessary.".... Perhaps most important, there is the challenge of cyborg augmentation of man's intelligence with the computer.... Among the researchers: a group at Stanford University under Prof. Bernard Roth ... and another group with Prof. Marvin Minsky at the M.I.T.-operated Project MAC (for "Machine-Aided Cognition"). As exercises, Minsky's group has built such gimmicks as a television camera "eye" and manipulator "hand," teamed with a computer, that can catch a ball thrown to it. A major achievement at the moment is a mobile device, hooked to a computer, that can distinguish individual child's building blocks and make simple decisions to fulfill commands on what to do with them. "So far, we are able to match this sort of general intelligence to about the 4-year-old level," says Minsky. "It has the barest ability to look around an ordinary room to see what's there and decide whether there are enough flat pieces to build something, or whether it can construct a 2-foot tower of blocks without the tower's falling over." The problem, says Minsky, is that "there is nothing yet that can absorb the variety, the large number of concepts" a human being can, or that can perceive and understand sensory information in what the researchers call "pattern recognition." Most computer researchers therefore think it logical to concentrate on cyborg combinations of man, performing the basic functions of pattern recognition and judgment, and computer, doing the intellectual dirty work. It is here that truly futuristic cyborg complexes begin to evolve.... |

________________ November 28, 1982 Spare-Parts Medicine The "electronic eye" is one of a growing list of artificial organs that physicians and scientists are now developing to help rehabilitate victims of injury and disease. Using the most advanced technology, they are creating devices that perform basic biological functions -- though still not as well as the organs nature provides. "Biological organs have been in the research and development stage for the last 100 million years," says Ioannis Yannas, a professor of polymer science and engineering at the Massachusetts Institute of Technology, "and that's when all the best work was done.".... ...Professor Yannas himself has developed a new type of artificial skin that helps burn victims to heal more quickly with less scarring than had previously been possible. More than 200 deaf persons now have electronic implants that give them a degree of hearing, the precursor to a device that promises to restore hearing acuity to a level close to normal by turning sound into electronic impulses and transmitting those impulses directly to the auditory nerve. More than two-dozen amputees have received artificial arms powered by motors hooked up to microcomputers, and similar computer-guided artificial legs -- including a system that allowed a paralyzed Ohio woman to take six, tentative steps earlier this month -- are under development. In an experimental program at the University of Utah, patients will receive artificial ureters and small-diameter blood vessels within the next year. And in another experimental program at the university, researchers have developed a polyurethane heart that is now ready to be implanted into the chest of a cardiac patient -- as soon as a patient fitting the medical requirements for such an artificial heart comes along. These devices and techniques extend an approach to medicine that began making a significant impact only about a generation ago. Artificial organs are more promising than transplants of natural organs, which are difficult to acquire and which the body [may] reject. Kidney dialysis machines, heart-lung machines, cardiac pacemakers, artificial heart valves and synthetic arterial grafts are all varieties of artificial organs.... A device that is ready for general use right now is the "Utah arm," designed by Stephen C. Jacobsen and his colleagues. Dr. Jacobsen ... began exploring how computer technology might improve the current generation of artificial arms, which an amputee controls with an awkward contortion of the body -- rounding the shoulders, for example, activates cables that flex the elbows or open a split-hook hand. Dr. Jacobsen's goal was an artificial limb that an amputee, with the help of microelectronics, could control in a natural way.... Dr. Jacobsen's arm, designed in modules for easy repair and replacement, exploits the electrical signals that muscles generate as they contract. When he fits the prosthesis on a lower-arm amputee, Dr. Jacobsen places electrodes on the biceps and triceps muscles. To flex the artificial arm, the amputee flexes his biceps muscle just as he would if he had a natural arm. The electrodes pick up the electrical signals and send them to a microcomputer located in the elbow, which translates the signals into a command to the arm's motor to flex the elbow. All of this happens instantaneously. If the patient is an upper-arm amputee, Dr. Jacobsen places the electrodes on the remnants of the deltoid muscle at the shoulder. Now fitted on 23 patients, the $10,000 arm can lift four pounds and can support 50 pounds when the elbow locks in any of 21 positions. But it is a long way from the prosthesis that Dr. Jacobsen says will be on the market within a few years. The second-generation arm, now in testing, has powered motion not only at the elbow but also at the wrist, hand, and upper arm. Mimicking the full motion of the natural arm is a formidable task, and it leaves Dr. Jacobsen in awe of evolution's design. "Biological systems are so much better and more versatile than anything we can make," he says. "We can make airplanes that fly faster than birds, but they don't mate, sing or sit in trees and look good. It's the same thing with the arm." In the decades ahead, says Dr. Jacobsen, the artificial arm may attach to a socket bonded directly to the amputee's bone.... |

| Visit the Rehabilitation Institute of Chicago's website and watch double-amputee, Jesse Sullivan demonstrate recent developments in artificial limbs! |

|